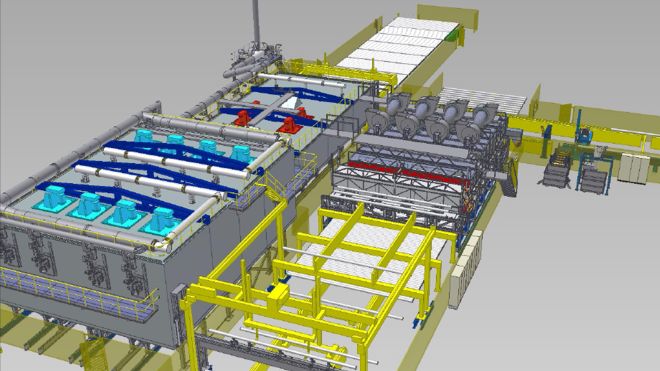

To accommodate high throughput capacities, continuous furnaces are employed for the homogenization of bars. The system comprises a furnace, an air cooling section, and a water quench. The furnace is equipped with a specialized lifting system for bar transport, which, in comparison to conventional lifting beams, minimizes energy losses and reduces maintenance efforts.

Benefits at a glance:

- Particularly energy-saving walking beam system

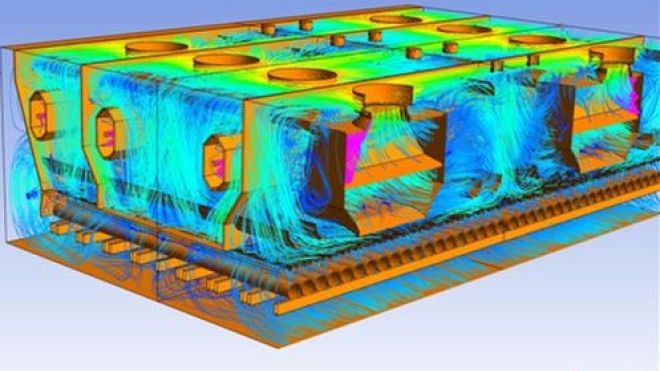

- High temperature accuracy

- Maximum throughput

- highly efficient self-regenerating high-speed burners

For high throughput capacities, continuous furnaces are used for the homogenization of bars. The system consists of a furnace, an air cooling section, and a water quench. The furnace is equipped with a special lifting-system for bar transport, ensuring lower energy losses and reduced maintenance efforts compared to conventional lifting beams.

Technical Highlights:

The precise control of the over-temperature achieved through the furnace construction by OTTO JUNKER provides better flexibility for mixed batches and enables the heat treatment of different diameters in close succession. Overall, this results in higher furnace throughput.

With OTTO JUNKER's multi-zone continuous homogenization furnace, the need for buffer capacity is minimized, as the furnace is sized to provide full capacity for each bar diameter.

The furnace systems generally consist of:

- Transfer unit

- Bar conveyor

- Continuously operated homogenization furnace with heating section and holding zone

- Transport system from the furnace to the cooling area

- Air cooling zone with high-convection cooling

- Water quenching

- Transport system for transfer

- Hydraulic unit for the entire equipment

- Electrical control equipment for the furnace and the cooling area

Loading and unloading of the furnace are done through small side doors to minimize energy losses.

The furnace comprises heating zones with high heat input into the bars, an equalization zone for temperature balancing and a long holding zone for homogenization

| diameter | 7" (178 mm), 8" (203 mm), 9" (228.6 mm) |

| length | 6,500 - 7,500 mm |

| weight | 437 - 655 kg |

Downloads

Phone +49 2473 601-0

+49 2473 601-0

E-Mail sales@otto-junker.com

sales@otto-junker.com