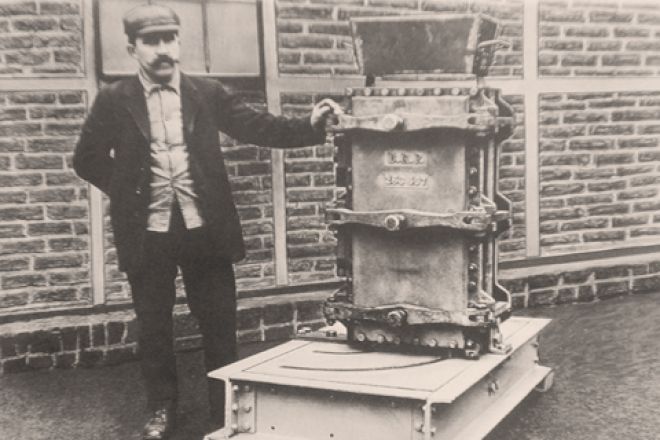

1913

Otto Junker‘s father, Andreas Junker, invents the water-cooled permanent mould for casting rolling slabs of copper which revolutionizes foundry operation in the non-ferrous semis industry worldwide.

From a small mechanical engineering workshop to a globally active group of companies

Otto Junker‘s father, Andreas Junker, invents the water-cooled permanent mould for casting rolling slabs of copper which revolutionizes foundry operation in the non-ferrous semis industry worldwide.

Otto Junker takes over the manufacture and sale of the water-cooled mould. The foundations of OTTO JUNKER GmbH have thus been laid.

In his father‘s garden Otto Junker is running his own makeshift machine shop, producing not only oil burners but also the water-cooled moulds. The OTTO JUNKER GmbH is founded.

After a series of trials, Hirsch, Kupfer- und Messingwerke AG, the largest brass works in Europe at that time, decided to install Andreas Junker‘s mould. The resulting amount of new orders for moulds overwhelmed Otto Junker‘s workshop in Stolberg.

Despite the remote location of Lammersdorf – tucked away in the Eifel – Otto Junker goes ahead with the construction of a new workshop there.

Andreas Junker passes away and Otto Junker had to give up his studies at the Technical University of Aachen.

Temporarily, he takes over the technical management of the von Asten and Lynen company together with the foremen of the brass works. At the same time he continues to build up his own factory in Lammersdorf. He converts the von Asten and Lynen foundry to electric melting operation. Moreover, he introduces he water-cooled mould to other brass works at home and abroad.

Otto Junker succeeds in gaining a foothold in the American brass industry with the water-cooled mould and the know-how of the brass hot-rolling process.

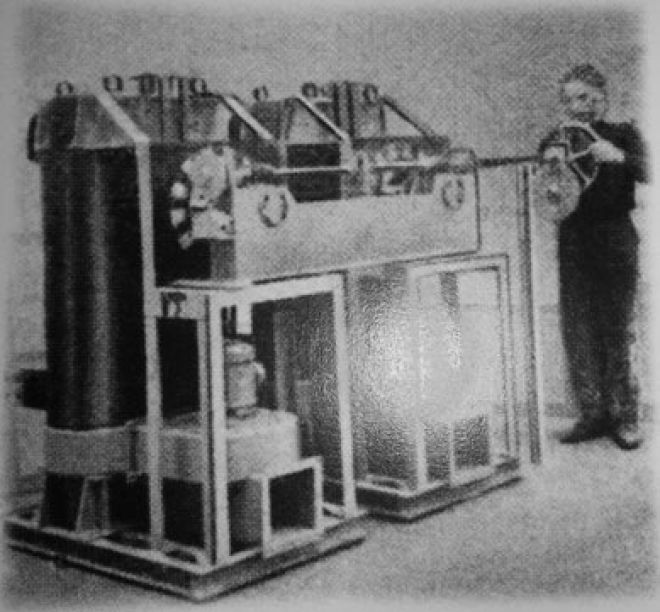

Development of an electrically heated pull-through annealing furnace line for brass strip. The line includes all equipment required for strip handling and pickling. This development proved highly successful so that about 200 installations of this type were built by 1963. Even fuel-fired versions were added later.

The range of resistance-heated annealing furnaces is extended and charging equipment for these furnaces is designed and built. This diversification helps overcome the lack of orders during the global economic crisis.

Establishment of a branch in Gevelsberg for smaller furnaces; manufacgture of chamber furnaces for automotive safety glass products.

Based on close cooperation with the major glass company St. Gobain, Junker develops a graphite rod resistor furnace which is highly successful in the foundry industry.

Expansion of furnace and machinery manufacturing facilities by a large assembly shop and an office building in Lammersdorf (west of the main road).

The foundry so far used for trials and demonstration purposes only, is upgraded into a jobbing foundry.

In plant engineering, the first mains-frequency channel-type induction furnaces for non-ferrous metals are built.

Start of the manufacture of transformers. This essentially promotes the sales of graphite rod resistor furnaces and later also the manufacture of induction furnaces.

Construction of a large shop building to accommodate cutting operations and the iron warehouse in a period of growing order volumes.

The plant at Lammersdorf is destroyed almost entirely.

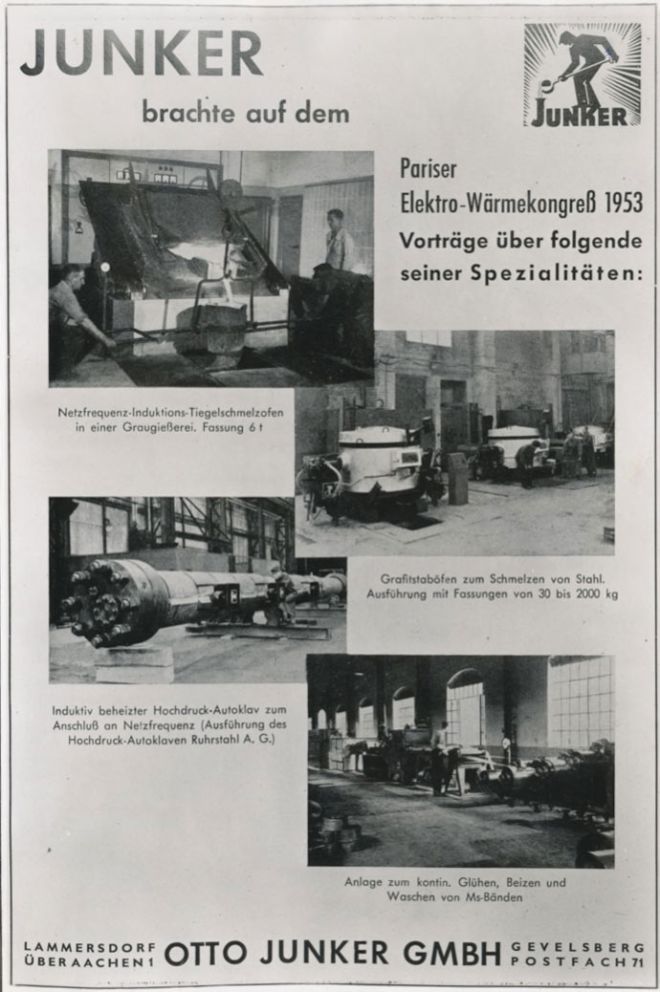

The manufacture of coreless mains-frequency induction furnaces starts.

Celebration of the 25th anniversary of the company.

Development of single-phase connection to three-phase power supply for coreless mains-frequency induction furnaces. Uniform load on the three supply phases is achieved by a phase balancing system. This design breaks new ground for use of induction furnaces and strengthens the position of OTTO JUNKER in the market. This development also gives rise to the blueprint for a new generation of induction-type billet heaters for non-ferrous metal billets.

Lectures are delivered on electric furnaces at the Electro-Heat Congress in Paris with special emphasis on coreless mains-frequency induction melting furnaces

A license is granted for manufacture of coreless mains-frequency induction furnaces to a company in the UK.

Construction of new production shops thanks to full order books.

First medium-frequency crucible melting furnace with statically tripled frequency by means of triductors.

Further expansion of the high-grade steel foundry.

Otto Junker receives honorary doctorate from the Technical University of Aachen.

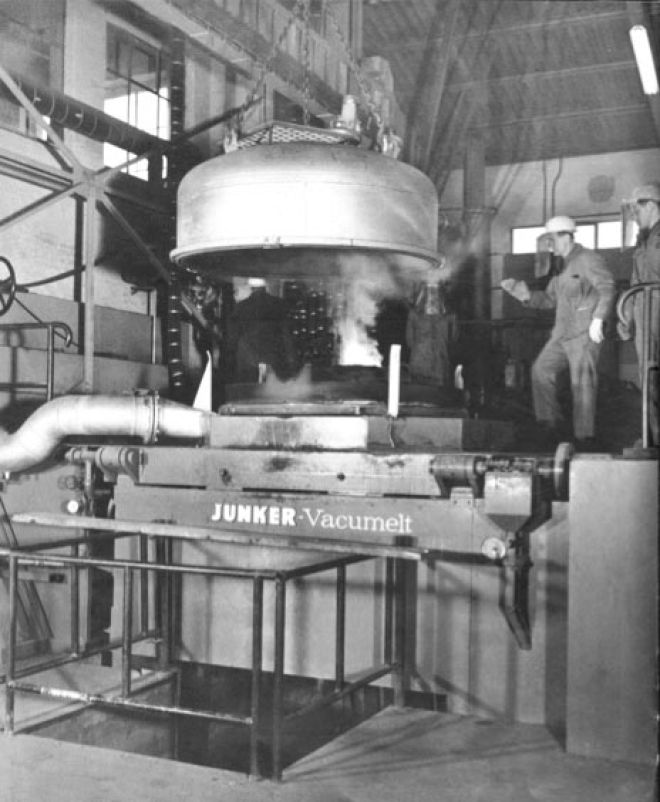

Installation of newly developed vacuum furnace in the in-house foundry to produce castings of high-quality steel alloys.

Another license for manufacture of coreless mains-frequency induction furnaces is granted to companies in India, Japan and South Africa.

Further production shops are built as well as a new company cafeteria.

The first gas-fired rapid heater is commissioned for non-ferrous metal billets.

Delivery of the first metal dosing furnaces for low-pressure aluminium die casting.

The first two larger vacuum induction furnaces for the vacuum treatment of 10 tonnes each of high-quality steel and nickel alloys go into operation at the customer's site.

The first orders are placed for mains frequency induction channel-type furnaces for grey cast iron with usable capacities of 20, 35 and 50 tonnes.

Commissioning of the first jet-heating large-chamber furnaces with a capacity of 20 t for annealing aluminium coils

Commissioning of the first strip flotation furnace for copper strips.

Development and manufacture of the first JUNKER pouring furnace for cast iron.

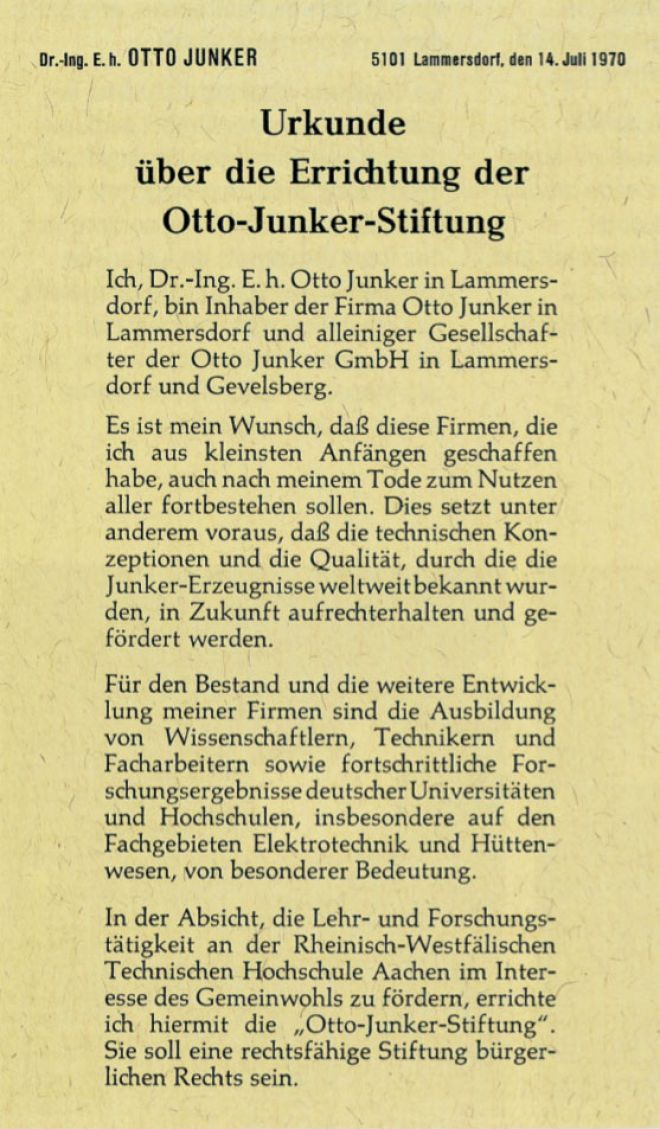

The OTTO JUNKER Trust is founded with the objective of promoting science and supporting young engineers in the field of electrical engineering and metallurgy at the Aachen university.

Otto Junker steps down from the board of management.

He appoints a Supervisory Board, of which he is elected Chairman.

Picture: Certificate of establishment of the Otto Junker Foundation

Molten metal transport containers by OTTO JUNKER are used for the first time for transporting molten aluminium in Germany.

Manufacture of large-sized furnace units:

Large batch-type annealing furnace with Jet Heating system; Mains-frequency channel-type induction furnace with a capacity of 100 tonnes of grey iron.

The first gas-fired rapid heater is delivered for copper billets.

The first continuous thin-strip annealing and pickling line for copper strip is put into operation.

First directly gas-fired furnace for recrystallization annealing of brass pipes.

Celebration of the 50th anniversary.

Delivery of the largest coreless mains-frequency induction furnace with short coil for heavy metal with a capacity of 120 t.

The JUNKER high-grade steel foundry delivers the world‘s largest ring bowl for bottle filling machines. The cast bowl of stainless and acid-resistant steel has a diameter of approx. 6 metres.

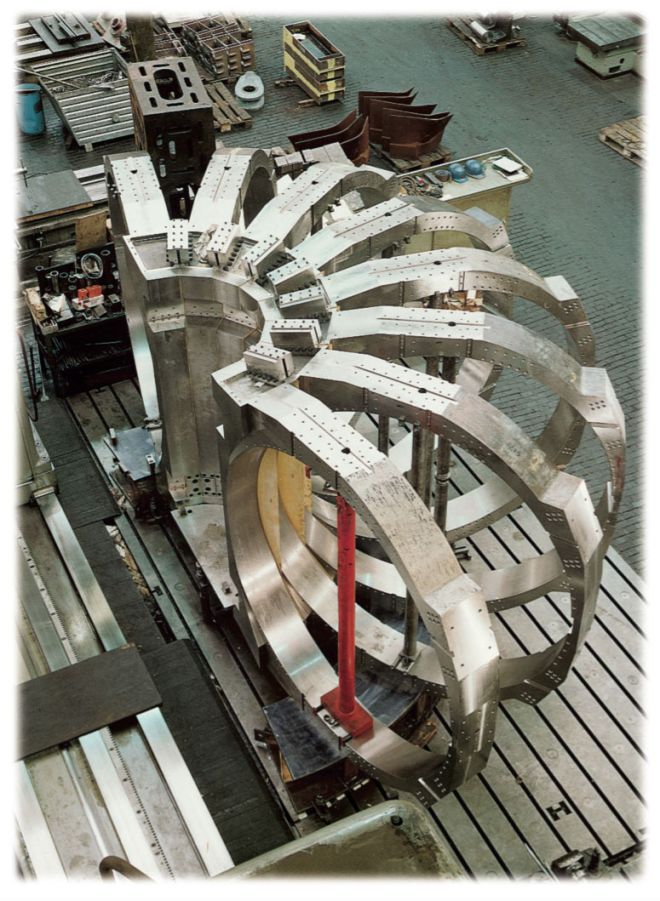

17 enclosures of special high-grade steel are cast by the JUNKER foundry for the TEXTOR plasma research facility at Jülich. These 4.8-tonne enclosures are designed to accommodate magnetic field coils.

Commissioning of the first powerful 1350 kW parallel oscillating circuit converter on a 2-tonne medium-frequency coreless induction furnace for melting steel.

Development of a 1,000 kW inductor for mains-frequency channel-type furnaces for aluminium.

The first coreless induction furnace (coating pot) for the continuous coating of steel strip with an Al/Zn alloy is put into operation.

Introduction of the multi-layer low-loss induction furnace coil for billet heaters – which reduces energy consumption significantly.

Death of Otto Junker: The Otto Junker Trust established in 1970 becomes the sole shareholder of OTTO JUNKER GmbH.

Commissioning of the first inductive strip heater installed in-line into a rolling mill for aluminium strip.

The first large gas-fired pit furnace is commissioned for heating aluminium rolling slabs at a high heat-up rate and superior temperature accuracy.

First high-convection furnace for recrystallization annealing of brass rods and pipes with JET heating system and chain conveyor.

Indirectly gas-fired high performance strip flotation furnace for annealing strip of copper based alloys with a particular focus on current environmental legislation in terms of energy and water management.

The OTTO JUNKER trust participates in establishing the Gesellschaft für Ur- und Umformen (EFU) for the development of new processes.

Acquisition of ELHAUS INDUSTRIEANLAGEN GmbH completing the portfolio of equipment for aluminium extrusion works

The safety and reliability of induction melting furnace operations is significantly enhanced by the introduction of JUNKER‘s furnace control system, JOKS.

IPW Ltd., UK, joins the JUNKER group, extending the product range by small-sized coreless medium-frequency furnaces.

The first high-power melting plant comprising two tandem units is put into operation. Each tandem unit consists of two 8,000 kW medium-frequency coreless furnaces with a capacity of 8 tonnes of grey cast iron (24-pulse thyristorized frequency converter).

Acquisition of the French company THERMIQUE & AUTOMATION producing special heat treatment equipment.

The high-grade steel foundry introduces a software program (MAGMA SOFT) to optimize its casting processes (e.g., with regard to cavity filling and solidification behaviour) and conduct numeric design simulations.

The high-grade steel foundry is ISO 9002 certified by LLOYD‘s Register.

JUNKER INDUSTRIAL EQUIPMENT s.r.o. is founded in the Czech Republic as an independent production unit to manufacture furnaces relying fully on OTTO JUNKER know-how.

OTTO JUNKER‘s furnace manufacturing division is DIN EN ISO 9001 certified.

First strip flotation furnace for aluminium strip for use in the automotive industry

A vertical high-throughput annealing section is commissioned, combining inductive pre-heating with convective heating of 350 to 750 mm wide and 1 to 4 mm thick heavy-metal strip.

Engineering, installation and commissioning of a complete melting operation, from dust collection through to charge make-up. Two ten-tonne coreless medium-frequency furnaces for tandem operation with a power rating of 8,000 kW form the heart of the French plant.

A heat treatment furnace line for aluminium plates for the aircraft industry is commissioned in a major European semi-finished products factory. The system achieves an outstanding temperature uniformity over the entire plate length of 36 m.

Construction of a new technology and office building.

Our office in Beijing opens.

Celebration of the company‘s 75th anniversary.

Introduction of 3D-CAD system Start-up of the largest coreless induction furnace for superheating and alloying primary magnesium with a capacity of 9 tonnes. The plant features multi-frequency technology and the novel Power Focus system.

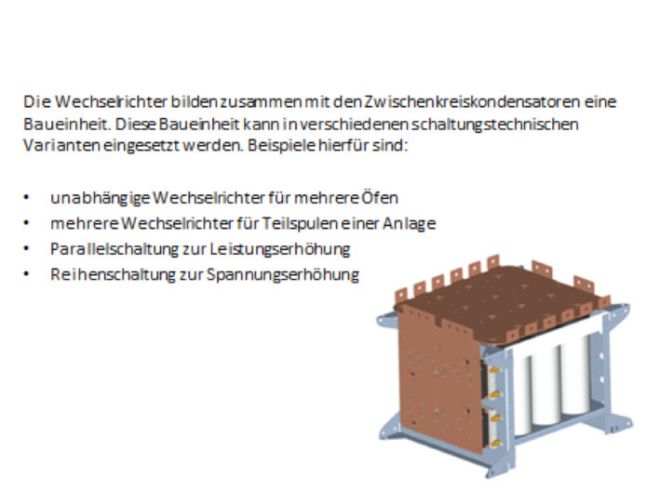

After years of development a patented frequency generator of the latest generation is presented. The grid-friendly converter uses thyristors of IGBT technology in the inverter. The new technology guarantees high availability and allows flexible use of the electric power pack.

The new machining centre is commissioned in the foundry for high-quality and efficient machining of high-tech castings.

Continuous strip annealing line with automatic furnace parameter set-up by process control via an expert system. The required grain structure (grain size) of the copper strip is simply entered into the system.

The newly developed OCP (Optical Coil Protection) sensor system is doing a successful job in monitoring induction furnace crucibles. Patent is granted in 2005.

Successful operation of an innovative automatic heat treatment line for VW Golf V aluminium castings.

The Chinese subsidiary, Junker Metallurgical Equipment, is founded in Shanghai.

Acquisition of the Dutch company Thermcon manufacturing fuel-fired melting furnaces and other equipment for the aluminium industry.

The largest roller-hearth furnace line for the annealing of copper pipes is delivered into China.

OTTO JUNKER opens a Middle East Representative Office in Dubai.

Acquisition of the majority interest in INDUGA Industrieöfen und Giesserei-Anlagen GmbH & Co. KG.

A valuable addition to the existing product range is thus achieved, particularly in the field of special induction furnace systems for melting and pouring copper materials.

The 1,000th Junker melting furnace is delivered to the German foundry industry; more than 2,500 Junker furnaces are running in Europe.

Acquisition of the Swedish company IUT manufacturing special heat treatment furnaces for aluminium.

Construction of a production hall with energy-saving hall heating and installation of an additional vertical lathe for the mechanical processing of steel castings.

Industrial use of the newly developed energy-saving coil in copper melting furnaces of Schwermetall Stolberg, reducing their copper melting energy consumption by 40 kWh/tonne or 9 %.

More than 100 IGBT frequency converters made by OTTO JUNKER are powering melting and heating equipment with great success.

Development and manufacture of special furnaces for refining silicon for photovoltaic applications.

Concentration on core competence and consolidation of individual subsidiaries, with partial integration of products and skilled personnel into the parent company.

Alongside the manufacturing companies and sales offices, INDUGA with its products remains an autonomous group company.

Relocation of INDUGA operations to the Lammersdorf headquarters site, yielding synergies through close cooperation from sales to manufacture and installation.

Start-up of a new sintering and heat-up system for INDUGA‘s electric low-pressure die casting furnaces

The foundry is equipped with an advanced ventilating system with heat recovery and external stack, including renovations to all roofing.

Inauguration of OTTO JUNKER high-efficiency strip annealers at Alu Norf: Energy consumption is reduced by reclaiming heat from strip rolling based on a numerical model of the annealing process.

Patent application is filed for ‚Kombi-Gas‘ - an innovative and energy-saving equipment design for heating aluminium logs and billets.

Development of a new type of strip flotation furnace in cooperation with the Technical University of Aachen (RWTH) - optimization based on numeric and physical flow simulation (fluid structure interaction): Patent application is filed for Strip Flotation Furnace ‚2VX®‘.

Pressurized pouring furnaces are provided with a newly developed stopper control system relying on a linear actuator.

Expansion of the machining shop of the high-grade steel foundry by another automatic machining centre.

Numerical models based on the ALU NORF system define a new state of the art in the market (AMAG, FATA OMAN, ALERIS DUFFEL; HUTA KONIN).

Energy savings of the KombiGAS billet heater exceed all expectations at SAPA OFFENBURG.

OTTO JUNKER starts-up a coreless furnace with reversing stirring circuit using phase-shifted IGBT modules:

This provides even better control of the bath movement.

Introduction of the SLE (Side Loaded Energy-saving) pusher furnace.

A new pusher furnace generation for reheating and homogenizing aluminium rolling slabs.

Implementation of a trial plant on an industrial scale to determine optimum cooling parameters for various aluminium alloys and plate or strip gauges.

Successful introduction of the double-stroke eyeletting strip joiner which was patented already in 2012.

OTTO JUNKER Metallurgical Equipment (Shanghai) Ltd. (JMS) is strengthening its Chinese and international market position by establishing its own assembly workshop in Changshu.

Manufacture of three vacuum melting furnaces of a new, alternative design. This makes OTTO JUNKER the only manufacturer capable of offering its customers a choice between two different vacuum furnace designs.

Versatile trial melting furnace relying on an IGBT frequency converter with variable circuit arrangements is installed in the OTTO JUNKER trial foundry.

Celebration of the 90th anniversary of the company.

Expansion of coilmaking shop by two production halls at the Lammersdorf site.

Commissioning of the longest floating belt furnace for aluminum.

Commissioning of the largest pusher furnace for aluminium rolling slabs, 1000 t

Successful start of the German Foundry Standard series in China.

OTTO JUNKER presents a new modular oven series:

JUPITER Line.

Founding of OTTO JUNKER India Pvt. Ltd. in Mumbai.

Development work in the field of battery recycling bears fruit First battery recycling furnace goes into production

Solutions for the transition to climate-neutral, green energy sources are offered by our OTTO JUNKER SOLUTIONS GmbH start-up with green technologies

OTTO JUNKER celebrates its 100th anniversary

100 years of innovation and transformation in the metal industry - OTTO JUNKER - a manufacturer of industrial furnaces and systems for melting and heat treatment of metals and for recycling scrap and Li-ion batteries as well as ‘Power to Heat’ energy storage systems.